Stator Potting Encapsulation

Stator Potting Encapsulation

- 产品详情

- 产品参数

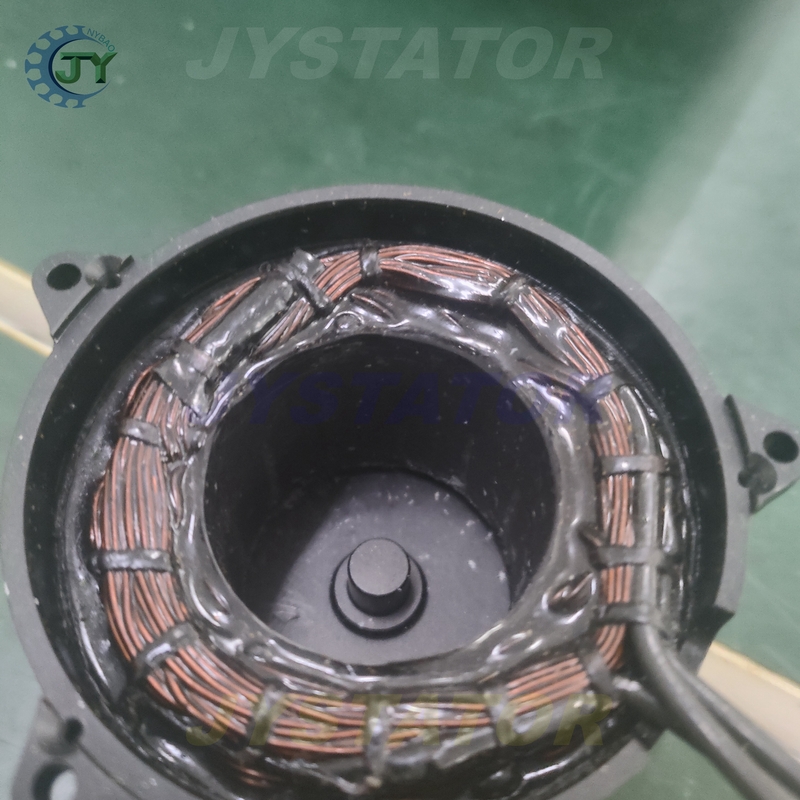

Stator Potting and Coil Encapsulation

For most of the stators, after the winding has been finished, a varnish impregnation coating will be applied to against vibration; while for two application, only varnish impregnation coating is not enough and need coil encapsulation;

1. When the motor is running underwater; it need coil encapsulation to protect the the stators and coils against from rust;

2. Whe the motor heat load is very high and need high thermal conductivity potting varnish to fill into the coils;

What motor potting Epoxy JYSTATOR used for Customs stators?

11T206-20290/7H01350013 Electrical Potting System is a black, filled, epoxy that has a moderate mixed viscosity and a long gel time.

This system is highlighted by low shrinkage and low exothermic properties. UL 1446 recognized as a potting compound up to 180C (class H) UL File No. E 210549. This system is designed for ambient cured applications requiring complete impregnation. System may be used with or without vacuum. The moderate viscosity and long gel time make this a viable system for high speed production or manual applications. The cured system has excellent thermal shock resistance.